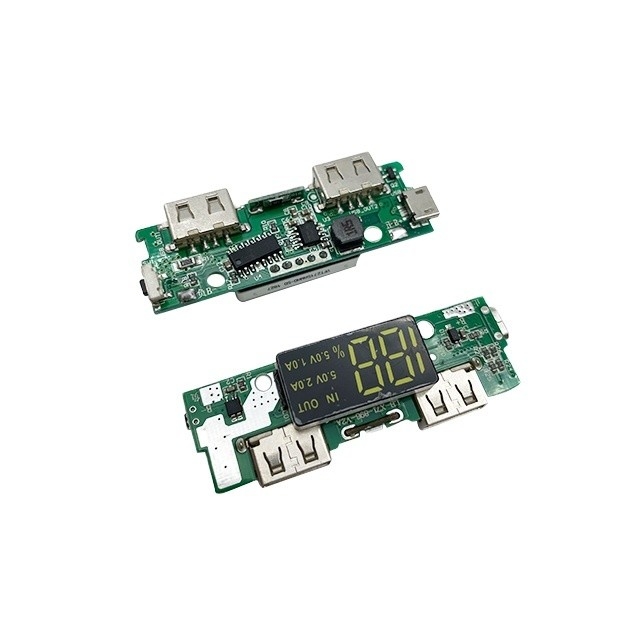

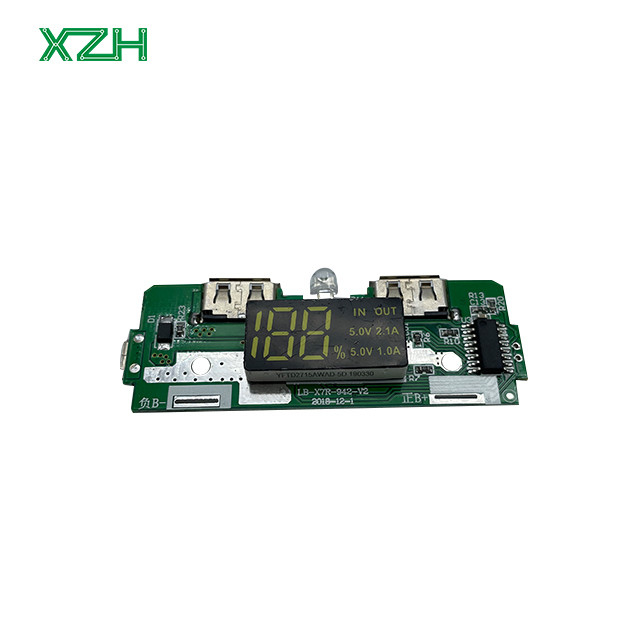

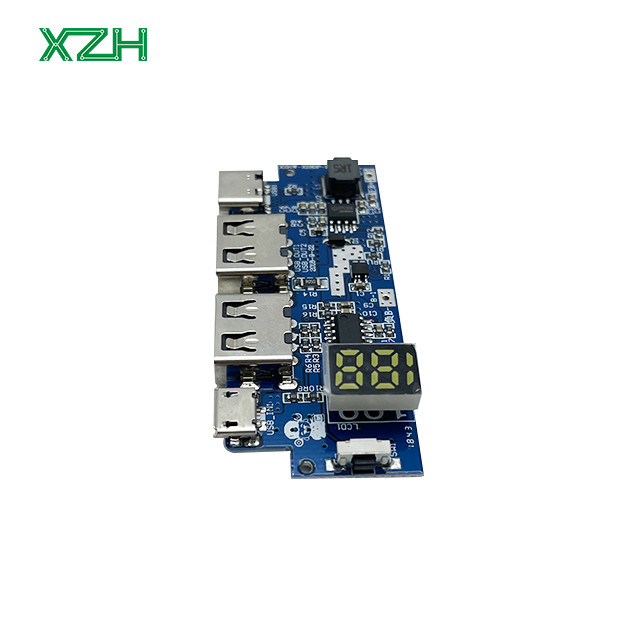

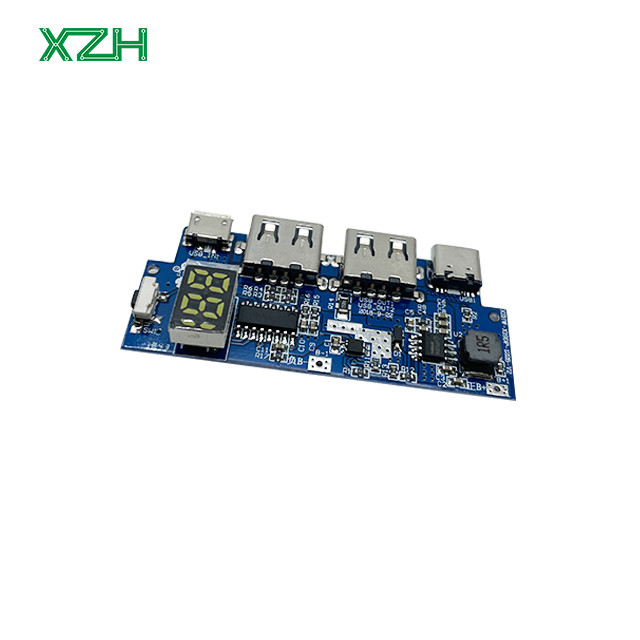

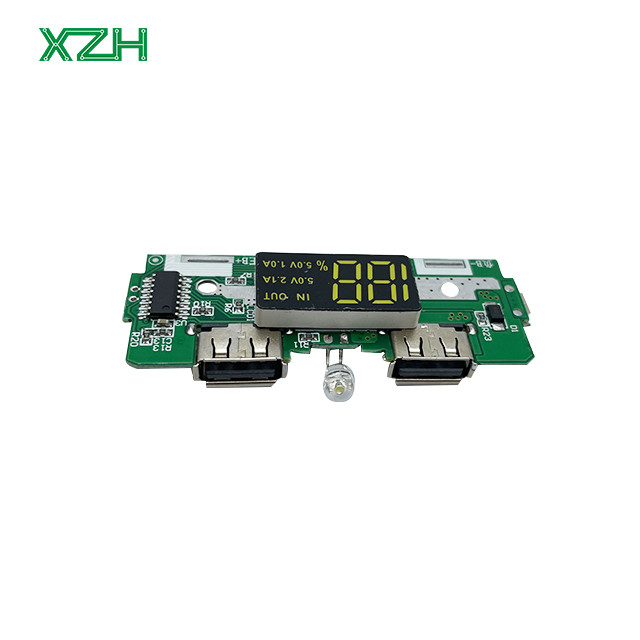

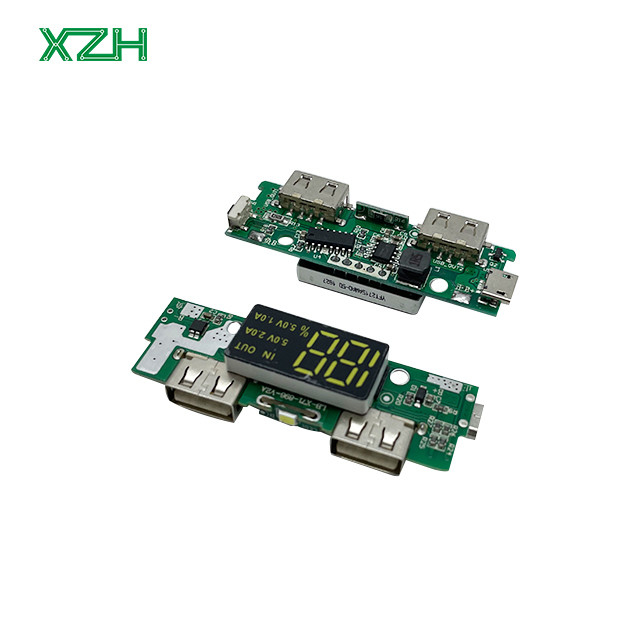

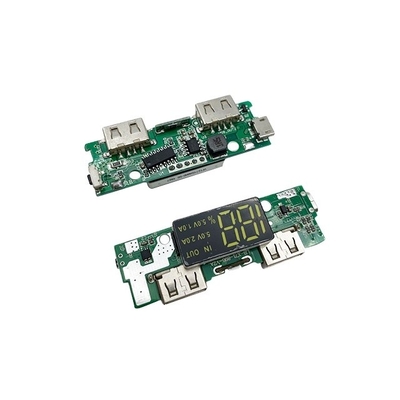

Customized Power Bank PCBA Assembly Solution for Professional Consumer Electronics

-

Highlight

PCBA Assembly Solution

,Professional Consumer Electronics PCBA

,Customized Power Bank PCBA

-

TypePower Bank Pcba

-

Supplier TypePower Bank PCBA

-

Product NamePower Bank PCBA

-

Surface FinishingHASL\OSP\immersion Gold

-

Base MaterialFR1, 22F, CEM-1, CEM-3, FR4, High TG, Aluminum, Ceramic, Rogers

-

Board Thicness0.20mm-4.0mm

-

Copper Thickness0.5oz-6oz

-

Solder Mask ColorGreen, Blue, White, Black, Yellow

-

Silk Screen ColorWhite, Black

-

PCBA ServiceSMT,DIP,Components Sourcing

-

Testing ServiceAOI X-Ray Function Test

-

Other NamePower Bank PCB Manufactuer

-

Place of OriginGuangdong, China

-

Model NumberXZH PCB

-

Minimum Order Quantity100 pieces

-

Price$2.30/pieces 100-499 pieces

-

Packaging Detailspacking in carton , Independent packaging

Customized Power Bank PCBA Assembly Solution for Professional Consumer Electronics

Details for PCB &PCBA

Base material | FR4,High-TG FR4,CEM3,aluminum, High Frequencey frequency(Rogers,Taconic,Aron,PTFE,F4B) |

Layers | 1-4 Layers(Alunimum), 1-32 layers(FR4) |

Copper Thickness | 0.5oz, 1oz, 2oz, 3oz,4oz |

Dielectric Thickness | 0.05mm, 0.075mm, 0.1mm,0.15mm,0.2mm |

board Core Thickness | 0.4mm,0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 3.0mm and 3.2mm |

Board Thickness | 0.4mm - 4.0mm |

Thickness Tolerance | +/-10% |

Aluminum Machining | Drilling, Tapping, Milling, Routing, Die-Punching, Break-off tab available |

Min Hole | 0.2 mm |

Min Track Width | 0.2mm (8mil) |

Min Track Gap | 0.2mm (8mil) |

Min SMD Pad Pitch | 0.2mm (8mil) |

Surface Finishing | HASL lead free,ENIG,Plated Gold,Immersion Gold,OSP |

Solder Mask Color | Green, Blue, Black, White, Yellow, Red, Matt Green, Matt Black, Matt Blue |

Legend Color | Black, White etc |

Assembly Types | Surface mount Thro-hole Mixed technology (SMT & Thru-hole) Single or double sided placement Conformal coating Shield cover assembly for EMI emission control |

Parts Procurement | Full Turnkey Partial Turnkey Kitted/Consigned |

Component types | SMT 01005 or larger BGA 0.4mm pitch, POP (Package on Package) WLCSP 0.35mm pitch Hard metric connectors Cable & wire |

SMT Parts Presentation | Bulk Cut tape Partial reel Reel Tube Tray |

Stencils | Laser-cut stainless steel |

Other Techniques | Free DFM Review Box Build Assembly 100% AOI test and X-ray test for BGA IC programming Components cost-down Function test as custom Protection technology |

Product Leading Time

Sample Lead time | Mass production lead time | |||

Single sided PCB | 1~3 days | 4~7 days | ||

Double sided PCB | 2~5 days | 7~10 days | ||

Multilayer PCB | 7~8 days | 10~15 days | ||

PCB Assembly | 8~15 days | 2~4 weeks | ||

Delivery time | 3-7 days | 3-7 days | ||

Package: Anti-static Package with carton | ||||

Customer Services

PCB Service

XZH Supply single-side, double –side board, multilayer boards (1-20 layers), Boards type:Rigid PCB(CEM, FR4), Flexible PCB, Rigid-Flex PCB, MCPCB(Aluminum PCB), Ceramic PCB, RF PCB, etc.

PCB Assembly&Components Sourcing

XZH offer Printed Circuit Board Assembly ,components Sourcing and complete solutions. what we can always gurantee is the best quality,competitive price and best service.

More Details or Other requirements welcome to Email and Chat with us.

FAQ

Q1.What is needed for PCB PCBA quotation?

A: PCB: Quantity, Gerber file and Technic requirements(material,surface finish treatment, copper thickness,board thickness ,...)PCBA: PCB information, BOM, (Testing documents...) Q2. What file formats do you accept for PCB PCBA production?

A: Gerber file: CAM350 RS274X PCB file: Protel 99SE, P-CAD 2001 PCB BOM: Excel (PDF,word,txt) Q3. Are my files safe?

A: Your files are held in complete safety and security.We protect the intellectual property for our customers in the whole process.. All documents from customers are never shared with any third parties. Q4. MOQ?

A: There is no MOQ in XZH.We are able to handle Small as well as large volume production with flexibility. Q5.Shipping cost?

A: The shipping cost is determined by the destination, weight, packing size of the goods. Please let us know if you need us to quote you the shipping cost.